![]() Welcome to Sylvan Studio

Welcome to Sylvan Studio

Services

Laser Engraving

Laser engraving is the most popular laser marketing technology in product identification and traceability.

Laser engraving is the practice of using lasers to engrave an object. This process involves using a laser marking machine to make permanent marking on different materials. Laser engraving is a process that evaporates materials into fumes to engrave permanent, deep marks. The laser beam acts as a chisel incising marks by removing layers from the surface of the materials. The laser hits localized areas with massive levels of energy to generate the high heat required for vaporization.

Rotary Engraving

Rotary engraving is the engraving method of rotating a cutting tool in a motorized spindle that moves through a substrate to create a groove at a specific depth and in the same geometry and width as the cutter tip.

Rotary engraving involves physically removing materials with a drill. The drill has a motorized spinning cuter that can engrave through the surface of almost any material.

Rotary engraving can be used to engrave items in a wide range of different materials, including a variety of plastics, acrylic, gloss, wood, ceramic, stone, and solid surface materials.

The benefits of a rotary engraving job are that the marks won’t fade. It works on virtually an materials, and it can require only a single manufacturing operation

Rotary engraving is a machining process that consists of “hollowing out” the materials using a drill. The materials is removed by cutting tools “engraving drills” of different shapes and sizes. This process is used to engrave characters, symbols, or shapes.

3D Printing

The action or process of making a physical object from a three dimensional digital model, typically by laying down many thin layers of materials in succession.

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of 3D printed objects is achieved using additive processes. In an additive process an object is created by laying down successive layers of materials until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out/ hollowing out a piece of materials or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less materials than traditional manufacturing methods.

3D printing is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of materials or a mould to manufacturing physical objects, it simply stacks and fuses layers of material. It’s typically fast, with low fixed setup costs and can create more complex geometrics than ‘traditional’ technologies, with an ever-expanding list of materials. It is used extensively in engineering industries.

3D printing is a process in which a digital model is turned into a tangible, solid three-dimensional object, usually by laying down many successive, thin layers of a material.

HOW DOES IT WORK

First, a virtual design of the object is made. This design will work like a blueprint for the 3D printer to read. The virtual design is made using computer-aided design (CAD). Software, a type of software that can create precise drawing and technical illustrations. A virtual design can also be made using a 3D scanner, which creates a copy of existing object by basically taking pictures of it from different angles.

Screen Printing

Screen printing is a popular printing method, using a process that presses ink through a mesh screen in order to create a printed design.

WHAT IS SCREEN PRINTING?

Screen printing is the process that involves transferring a stenciled design on a flat surface with ink, a mesh screen, and a squeegee.

Although paper and fabric are the most typical of surface that are used in screen printing.

Screen printing is the process of transferring a stenciled design onto a flat surface using a mesh screen, ink and a squeegee. Fabric and paper are the most commonly screen-printed surfaces, but with specialized inks it’s also possible to print onto wood, metal, plastic, and even glass. The basic method involves creating a stencil on a fine mesh screen, and pushing ink through to create an imprint of your design on the surface beneath.

WHY IS SCREEN PRINTING USED?

One of the reasons that the scree printing technique is so widely used it because it produces vivid colors, even on darker fabrics. The ink or paint also lies in layers on the surface of the fabrics or paper, which gives a print pleasingly tactical quality.

The technique is also favored because it allows the printer to easily reproduce a design multiple times. Because the same stencil can be used to replicate a design again and again it’s very useful for creating multiple copies of the same garment or accessory.

THE SCREEN PRINTING PROCESS

There are different methods of screen printing, but they all involve the basic technique.

STEP 1: THE DESIGN IS CREATED

- To start, the printer takes the design they want to create on the finished product, and print it out onto a transparent acetate film. This will be used to create the stencil.

STEP 2: THE SCREEN IS PREPARED

- Next, the printer will choose a mesh screen to suit the complexity of the design, and the texture of the fabric being printed. The mesh screen is then coated with a layer of light reactive emulsion, which will harden when developed under bright light.

STEP 3: THE EMULSION IS EXPOSED

- The acetate sheet featuring the design is then laid onto the emulsion-coated screen, and the whole thing is exposed to a very bright light. The light hardens the emulsion, so the parts of the screen which are covered by the design remain in liquid form.

STEP 4: THE EMULSION IS WASHED OFF, CREATING THE STENCIL

- After the screen has been exposed for a set time, the areas of the screen not covered by the design on the screen for the ink to pass through.

- The screen is then dried, and the printer will make an necessary touch-ups or connections to make the implant as accurate as possible to the original design. The stencil is now ready to be used.

STEP 5: THE ITEM IS PREPARED FOR PRINT

- The screen is then placed on the printing press. The item or garment being printed is laid down flat onto the printing board, underneath the screen.

STEP 6: THE INK IS PRESED THROUGH THE SCREEN ONTO THE ITEM

- The screen is lowered down onto the printing board, ink is added to the top end of the screen, and a squeegee is used to pull the ink along the full length of the screen. This presses the ink through the open areas of the stencil, imprinting the design on the product underneath.

- If the printer creates multiple items, then the screen is raised and the new garment is places onto the printing board. The process is then repeated.

STEP 7: THE PRODUCT IS DRIED, CHECKED AND FINISHED

- The printed product then passes through a dryer, which ‘curses’ the ink and creates a smooth, colorfast finish. The final product will be checked an washed throughly to remove any residue before being presses on its new owner.

Embroidery

Embroidery is a decorative art form using fabric, needles, and thread designed to add texture and embellishment.

Embroidery is the art or stitching embroidery stitched on fabric surfaces with threads/embroidery floss and other materials.

Digital Printing

Digital printing is the process of printing digital-based images directly onto a variety of media substrates.

Digital printing refers to methods of printing from a digital-based image directly to a variety of media. Meaning, it goes directly from your PDF file, for instance, straight to the digital printer.

Tackle twill

Tackle Twill is an embroidery method that involves replacing part of a design with fabric instead of thread to save on stitch count or create a unique look.

Free Delivery

Order over $499.00.

Secure Payment

Visa, MasterCard, AMEX, Discover

Chat Support

Mon - Fri: 9am - 5pm EST.

Member Discount

Using Coupon Code.

© Sylvan Studio | All Rights Reserved

Ribbons

Ribbons

Rosettes

Rosettes

Banners & Sashes

Banners & Sashes

Medals

Medals

Trophies

Trophies

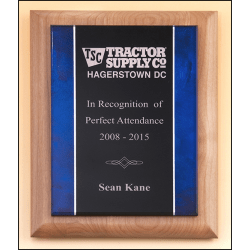

Plaques

Plaques

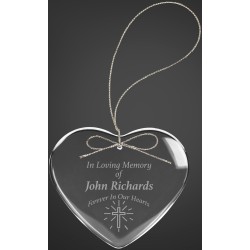

Crystal & Glass

Crystal & Glass

Acrylics

Acrylics

Personalized Gifts

Personalized Gifts