![]() Welcome to Sylvan Studio

Welcome to Sylvan Studio

Custom Rotary Engraving Services

Rotary engraving is a process that physically removes material with a drill. It involves rotating a cutting tool in a motorized spindle through a substrate to create a groove at a specific depth and in the same geometry and width as the cutter tip.

The drill has a motorized spinning handle that engraves the surface of an award. You can use rotary engraving on a wide range of materials including a variety of plastics, acrylic, glass, wood, ceramic, stone, and solid surface material.

How Custom Rotary Engraving Creates Stunning Designs

Rotary engraving creates marks that won’t fade by cutting deep into a surface. It works on virtually any material and requires only a single manufacturing operation.

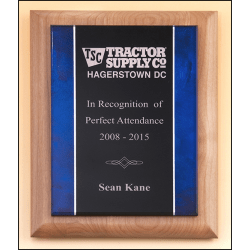

Rotary engraving is a machining process that consists of “hollowing out” an award surface using drills of different shapes and sizes. You can engrave characters, symbols, and shapes to create a refined look enhanced with paint and metallic inlays. This technique works well on high-end materials including metal and glass.

An engraved plaque or trophy also has a tactile advantage over laser-marked awards. Engraving creates a distinct feel that separates your design from the crowd. And because engraving has been used for centuries, it also conveys a sense of tradition and brevity.

The Rotary Engraving Process

Design Consultation

Our team reviews the purpose of your award and branding elements to create a design that encompasses the tone of the honor and event. We discuss material selection, typography, finish and decorative elements before moving forward with the engraving process.

Proofing

Once we mock up the initial design, you will review the digital proof to make final recommendations before engraving begins. Our team can also provide a physical sample if necessary. Your input guides our revisions process, and we rely on your review to confirm names, dates and titles.

Rotary Engraving

Our rotary engraving machine is calibrated based on your specs and award material. This type of graving offers extreme precision, allowing us to produce intricate designs. Depending on the cutter tip and engraving surface, we may make several passes to ensure the proper depth and clarity.

Delivery

Each custom rotary engraved award receives a final inspection to verify accuracy. We secure your awards in packing materials to prevent scratches and debris accumulation. We offer delivery and pickup options for your convenience.

Best Materials for Rotary Engraved Awards

Metal: Brass, stainless steel, gold, silver and bronze are effective options for high-end plaques, nameplates, and trophies. Metal allows for crisp engravings that work well with paint-filling for effective contrast.

Wood: The natural aesthetic of wooden awards produces a classic look. Depending on the hardness of the wood, rotary engraving can make deeper cuts and defined lines.

Acrylic: This material permits smooth engravings in clear, frosted and colored acrylic. You can frost engravings to create contrasting designs.

Plastic: Plastic is a budget-friendly material that is suitable for precise engravings, especially for bulk orders. Rotary engraving can reveal contrasting colors in multi-layer laminate plastics.

Stone: Marble, granite and quartz are bold options for engravings. Rotary engraving provides smooth or textured finishes to enhance readability.

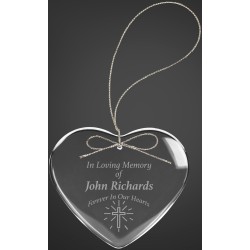

Glass: Crystal and glass add a touch of elegance to trophies and awards. This material is ideal for deep-carved engraving and 3D designs enhanced by beveled edges and tinting.

Ceramic: Glazed ceramic is effective for engraved creations. Include subtle lines and details to create a soft contrast.

Unmatched Craftsmanship at Sylvan Studios

Your vision becomes our passion, and we pride ourselves on producing high-quality plaques, trophies and awards. With decades of experience under our belts, we’ve encountered diverse orders with unique specifications that have helped us expand our skillset. Our team takes intangible concepts and produces unique creations that exemplify your organization, brand, recognition and recipient. Customer collaboration is crucial to our process, and we maintain open communication to ensure we design an award that exceeds your expectations.

Elevate Your Awards with Custom Rotary Engraving

Whether you’re just starting your search or know exactly what you’re looking for, the team at Sylvan Studios can provide the top-tier products you need to make a lasting impression. Contact us to learn about our catalog and design services.

FAQs

How does rotary engraving differ from other engraving methods, like laser or sandblasting?

Rotary engraving uses machinery to cut into a surface. As the name implies, laser engraving uses a beam of light to etch into the material, while sandblasting involves pressurized abrasive substances.

What role does design consultation play in creating an impactful engraved award?

During a consultation, you can discuss your preferences and expectations. Our team will provide suggestions based on your specifications, and you will work together to find the right solution for your award order.

Does the rotary engraving process accommodate highly detailed or complex designs?

It depends on the material and design, but rotary engraving generally supports fine details and designs.

Can I preview a proof of the engraving design before production begins?

Yes. We will provide you with a physical or digital proof for you to review before we begin the design process.

Free Delivery

Order over $499.00.

Secure Payment

Visa, MasterCard, AMEX, Discover

Chat Support

Mon - Fri: 9am - 5pm EST.

Member Discount

Using Coupon Code.

© Sylvan Studio | All Rights Reserved

Ribbons

Ribbons

Rosettes

Rosettes

Banners & Sashes

Banners & Sashes

Medals

Medals

Trophies

Trophies

Plaques

Plaques

Crystal & Glass

Crystal & Glass

Acrylics

Acrylics

Personalized Gifts

Personalized Gifts