Engraving is a popular design technique for trophies, plaques and other custom awards. It’s an effective way to add a personal touch or intricate pattern that leaves a lasting impression on the recipient. Laser and rotary engraving involve carving material from the surface of an award. They differ in method and process, but both create unique recognition pieces.

How Laser and Rotary Engraving Work

Laser engraving: This type of engraving uses a high beam laser to vaporize the surface of an award’s substrate, leaving a cavity. You can use a laser to engrave, etch and mark trophies and plaques to produce different textures and effects.

Rotary engraving: Also known as traditional engraving, the rotary process uses a spindle and bit to physically scratch the award surface. The bit is guided by mechanical equipment that follows a computerized design.

Differences Between Laser and Rotary Engraving

Precision and Detail

Laser engraving is effective for crafting sharp corners and fine lines. You can engrave small print, logos and images with clean cuts. This method also allows you to alter awards without affecting their structural integrity since the laser doesn’t touch the surface.

While it may not provide the minute details of a laser, rotary engraving still produces detailed line work. It creates a deeper cut with more durable marks that are better suited to large fonts and simple shapes. The depth of the engraving yields a more tactile fabrication for a lasting impression.

Material Compatibility

The heat from a laser may affect how it interacts with the award material. It’s more favorable for materials like glass and crystal, as there’s less chance of cracking and chipping caused by physical contact. Wood is an option if you want a burnt engraved style with precise contrast. Soft metals aren’t ideal for laser engraving, but coated alternatives allow the laser to reveal crisp lines in the base metal.

Wood trophies and plaques are excellent materials for rotary engraving, especially if you want to use inlays or paint to enhance the design. Brass, aluminum, stainless steel and other metals also take well to traditional engraving. The bit can cut deeper into the metal, allowing for a more defined etching. Glass and crystal are more likely to break under the pressure of a rotary machine.

Cost and Efficiency

Laser engraving offers faster production time, especially for bulk orders. The digital software also allows for quick adjustments and process automation. Lasers have lower operational costs because the lack of contact helps maintain the equipment’s integrity. Rotary engraving is a slower process but produces higher quality marks that withstand wear and tear. The machinery also requires consistent maintenance, as you have to replace the bit regularly.

Aesthetic Flexibility

Using laser engraving to customize trophies and awards allows for more intricate, high-contrast concepts. That’s important if you are working on a small surface or want to include linework, logos or images. This type of engraving also yields clean lines without rough edges. However, it doesn’t provide the tactile feel provided by rotary engraving.

Using rotary engraving produces a more traditional look with bold cuts that stand out on metal and wood. It creates a handcrafted appearance that may be preferable for individual awards, recognition pieces and multidimensional plaques.

Benefits of Laser and Rotary Engraving on Awards

Laser engraving:

- Consistent quality for detailed patterns

- Versatility on various materials

- Quick turnaround times

- Minimal setup

- Smooth finish

- Minimal material waste

Rotary engraving:

- High-end aesthetic

- Polished and oxidized finish options

- Timeless and elegant look

- Long-lasting designs

- Options for inlays and paint fills

Custom Engraved Awards from Sylvan Studio

Whether you need a plaque for a work event or a trophy for a sports competition, Sylvan Studios can help you find the award to suit your needs. We offer a variety of trophies, medals, banners, ribbons, rosettes and more. Contact us for production and pricing information.

Ribbons

Ribbons

Rosettes

Rosettes

Banners & Sashes

Banners & Sashes

Medals

Medals

Trophies

Trophies

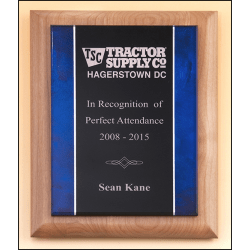

Plaques

Plaques

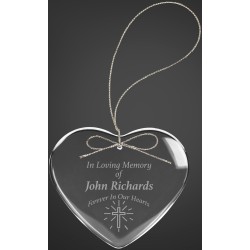

Crystal & Glass

Crystal & Glass

Acrylics

Acrylics

Personalized Gifts

Personalized Gifts